BCR-36623 - Battery Care Requirements F-TYPE (X152) 2020

BCR-36623 - Battery Care Requirements F-TYPE (X152) 2020

PUBLISHED: 08-AUG-2018

2020.0 F-TYPE (X152), 414-00

BATTERY AND CHARGING SYSTEM - GENERAL INFORMATION

BATTERY CARE REQUIREMENTS (G2283223)

DESCRIPTION AND OPERATION

1. INTRODUCTION

This document defines the requirements for care and maintenance of lead acid startup and auxiliary batteries, and the standard of battery care at retailers for new vehicles.

This procedure applies to all types of 12V lead acid startup and auxiliary batteries (if equipped) used in Jaguar and Land Rover vehicles whether they are:

- Conventional flooded technology

- Absorbed Glass Mat (AGM)(also known as Valve Regulated Lead Acid (VRLA)) technology.

AGM batteries offer improved resistance to cycling, due to Stop/Start applications.

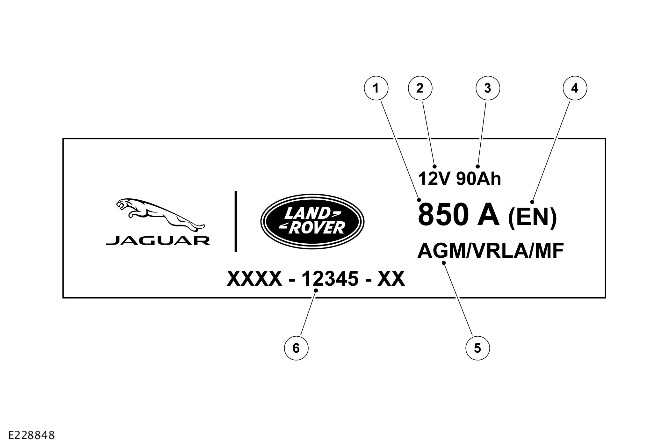

| NUMBER | DESCRIPTION | DETAIL |

|---|---|---|

| 1 | Battery rating |

|

| 2 | Battery voltage | (V) |

| 3 | Battery nominal capacity | Ampere hour (Ah) |

| 4 | Battery test standard |

|

| 5 | Battery type |

|

| 6 | Jaguar Land Rover (JLR) part number |

NOTE:

Flooded cell lead acid batteries, do not have a battery type marking on the battery label.

In order to prevent damage to the startup battery and auxiliary battery and make sure that they have a satisfactory service life. The processes detailed within this document must be followed.

It is important to note the following:

- All new vehicles leave the factory with either a transit relay installed and/or have a transit mode programed into the vehicle control modules. The transit relay must be removed (where applicable). The transit mode disabled (where applicable) using the Jaguar Land Rover (JLR) approved diagnostic equipment. This is to be done, not more than 72 hours before the customer takes delivery.

- The startup battery and the auxiliary battery can be discharged by the following mechanisms:

- Self discharge: A lead acid battery will very slowly discharge itself due to its own internal chemical processes whether it is connected to a vehicle or not.

- Quiescent discharge: The vehicle electrical systems when connected to the startup battery will draw charge from the startup battery.

Transit Relay Installation Summary

| JAGUAR | LAND ROVER | |

|---|---|---|

| Vehicles with transit relay installed | X152 and X351. | Not equipped. |

| Vehicles without transit relay installed | X260, X540, X760 and X761. | L405, L494, L462, L538, L550 and L560. |

The 12V lead acid startup and auxiliary batteries rely on internal chemical processes to create a voltage and deliver current. The startup and auxiliary battery internal chemical processes can be permanently affected, if the battery is allowed to:

- Self discharge over a period of time.

- Quiescent discharge over a period of time.

- Be stored in a discharged state.

To decrease the quiescent discharge when the vehicle is not in use (parked or stored), store the smart key more than 5 m (16 ft) away from the vehicle.

NOTES:

- Absorbed Glass MAT (AGM) batteries are fully sealed and cannot have the electrolyte level topped up.

- Retailers have a responsibility to make sure that only vehicles with a fully charged startup battery, are processed through the distribution selling chain.

2. GENERAL RULES FOR BATTERY CARE

2.1 RETAILER SHOWROOM/DEMONSTRATION VEHICLES

Vehicles used as retailer demonstrator(s), in a showroom, must be connected to a Jaguar Land Rover (JLR) approved showroom support unit capable of delivering 50A. This will prevent the startup battery from being damaged.

Vehicles used as retailer demonstrator(s), in a showroom, must be taken out of transit mode or have the transit relay removed. For additional information on the transit relay installation, refer to the Transit Relay Installation Summary table (section 1 of this procedure).

Vehicles used as retailer demonstrator(s), in a showroom, must have the starter motor, horn and wiper fuses removed as a minimum.

For additional information, refer to:Showroom Preparation (101-02, Description and Operation).

WARNING:

Jaguar Land Rover (JLR) approved showroom support units are only required to be turned on during showroom opening hours, outside these hours switch off all JLR approved showroom support units.

NOTE:

For retailers who do not have floor sockets installed in the showroom, a slave battery process has been outlined below. The slave battery process is only a temporary process until floor sockets are installed in the showroom. The retailer is responsible for making sure the process is set up and is also responsible for the procurement of slave batteries and other supporting equipment. The retailer is also responsible for developing a conformance plan to install the floor sockets.

2.1.1 RECOMMENDED SLAVE BATTERY RESPONSIBILITIES/PROCESS

Showroom Representative Responsibilities

- If a Jaguar Land Rover (JLR) approved showroom support unit is not available for a vehicle that is being used for display purposes in the retailer showroom. Then a slave battery must be installed in the vehicle while on display in the retailer's showroom.

- All vehicles installed with a slave battery must be logged and tracked by a nominated showroom representative who has been trained in the Battery Care Requirements process.

- For additional information, refer to the following Excellence training courses Battery Care Requirements EDASS00025_0814 and Good Battery Care EDAS400059_1114

- A list of the Vehicle Identification Number (VIN) details must be provided to the department where the original vehicle startup and/or auxiliary battery will be stored and maintained.

- Make sure the installation of the slave battery is coordinated with the workshop department and installed in a timely manner.

- Check on a daily basis for a 'low battery' warning indicator in the vehicle Instrument Cluster (IC). If required, contact the workshop department to charge the slave battery.

- Make sure that the slave battery condition is checked on a weekly basis using the Midtronics EXP-1080. If required, contact the workshop department to charge the slave battery.

- When the display vehicle has been sold, notify the workshop department to install the original startup battery (in a fully charged state) within 72 hours of vehicle handover to the customer.

- When the display vehicle is being returned to the vehicle storage compound, notify the workshop department to:

- Install the original startup battery (in a fully charged state).

- Refit the transit relay (if required).

- Put the vehicle into transportation mode.

- Record all startup battery inspections and battery charging dates and supporting information on the 'Showroom and Slave Battery Condition Report Form'.

- For additional information, refer to:Showroom and Slave Battery Condition Report Form (414-00, Description and Operation).

Workshop Representative Responsibilities

- Removal of the original startup battery from the vehicle.

- Installation of the slave battery to the display vehicle.

- Clearly label and identify a slave battery.

- Attach the slave battery identification tag JLR-415-010 (available from the Jaguar Land Rover (JLR) equipment website) onto the vehicle keys, identifying that the vehicle has a slave battery installed.

- Check, maintain and record the original startup battery condition information in accordance with the JLR storage procedure and policy.

- For additional information, refer to:Showroom and Slave Battery Condition Report Form (414-00, Description and Operation).

- Make sure that the slave battery has the same part number as the original startup battery installed to the display vehicle.

- Make sure the TOPIx procedure is followed for the removal and replacement of the original vehicle startup battery.

- Install the original vehicle startup battery within 72 hours of vehicle handover to the customer.

- Make sure if the display vehicle is being returned to the vehicle storage compound the original startup battery is installed (in a fully charged state). Install the transit relay (if required) and put the vehicle into transportation mode.

- Remove the slave battery identification tag JLR-415-010 from the vehicle keys, once the original startup battery has been installed.

- The original startup battery should be stored separately and clearly identified with the Vehicle Identification Number (VIN) from the vehicle from which it was removed.

2.2 SOFTWARE REFLASH, SYMPTOM DRIVEN DIAGNOSTICS WORK OR IGNITION ON RELATED WORKSHOP ACTIVITIES

Due to the high electrical current demand and high startup battery discharge that can occur when the following are done on the vehicle:

- Vehicle software re-flash activities.

- Symptom Driven Diagnostics (SDD) work or any diagnostic work using the Jaguar Land Rover (JLR) approved diagnostic equipment.

- Ignition ON (Power Mode 6) related work in the workshop.

Vehicles that are undergoing such activities must have a JLR approved battery support unit capable of delivering 50A or more. JLR approved battery support units can be found on the JLR tooling website.

CAUTION:

Do not download any software with either or both the transit mode ON or the transit relay installed, this could damage vehicle modules.

2.3 EXTENDED VEHICLE REWORK

For any extended vehicle rework that results in consuming vehicle startup battery power a Jaguar Land Rover (JLR) approved battery support unit should be connected.

For additional information, refer to:Battery Support Unit Connection Procedure (414-00, General Procedures).

2.4 JUMP STARTING NEW VEHICLES BEFORE THEY HAVE BEEN DELIVERED TO THE CUSTOMER

- It is the retailers responsibility to make sure the battery is not allowed to discharge by following the instructions and processes defined in this manual.

- If it is necessary to jump start a new vehicle due to a discharged startup battery whilst the vehicle is in the retailers care. The startup battery on the vehicle must be replaced with a new startup battery prior to delivery to the customer, at the retailers liability.

- The vehicle should also undergo investigation as to why the startup battery became discharged.

- Do not connect the jump lead to the negative (-) terminal of the startup battery. Always connect to the recommended earth point, as defined in the owners handbook or service documentation for the vehicle.

2.5 ABSORBED GLASS MAT BATTERIES

CAUTION:

Absorbed Glass Mat (AGM) batteries must not be charged to more than 14.8V. If a AGM battery is charged to more than 14.8V, this will damage the AGM battery.

Absorbed Glass Mat (AGM) batteries must be tested with a capable battery tester. See the 'EQUIPMENT' section (section 5 of this procedure).

NOTE:

Do not disconnect the startup battery with the engine running, because under these conditions the generator can give a very high output voltage. This high transient voltage will damage the electronic components in the vehicle. Loose or incomplete startup battery connections may also cause high transient voltage.

3. HEALTH AND SAFETY PRECAUTIONS

WARNINGS:

- Lead acid battery cells contain sulphuric acid and a explosive mixture of hydrogen and oxygen. It is necessary that the following safety precautions are observed.

- Lead acid batteries emit highly explosive hydrogen at all times, particularly during charging. To prevent any potential form of ignition occurring when working in the vicinity of a battery:

- Do not smoke or use a naked flame when working near lead acid batteries.

- Avoid sparks, short circuits or other sources of ignition near lead acid batteries.

- Switch off current before making or breaking electrical connections.

- Make sure that the battery charging area is well ventilated.

- Make sure that the charger is switched off when:

- Connecting the battery charger to a battery.

- Disconnecting the battery charger from the battery.

- Always disconnect the ground cable from the battery terminal first and reconnect it last.

- Lead acid batteries contain sulphuric acid, which is poisonous and highly corrosive. To prevent personal injury, or damage to clothing or the vehicle, the following working practices should be followed when topping up, checking electrolyte specific gravity, removal, installing or carrying batteries:

- Always wear suitable personnel protective equipment:

- A rubber apron

- Safety glasses or visor

- Rubber gloves.

- If acid is spilled or splashed onto clothing or the body, it must be neutralized immediately and then rinsed with clean water. A solution of baking soda or household ammonia and water may be used as a neutralizer.

- In the event of contact with the skin, drench the affected area with water. In the case of contact with the eyes, bathe the affected area with cool clean water for approximately 15 minutes and seek urgent medical attention.

- If battery acid is spilled or splashed on any surface of a vehicle, it should be neutralized and rinsed with clean water.

- Heat is generated when sulphuric acid is mixed with distilled water. If it becomes necessary to prepare electrolyte of a desired specific gravity, slowly pour the concentrated sulphuric acid into the distilled water (not the water into the acid). Add small amounts of acid to the distilled water, while stirring. If the electrolyte becomes hot while the sulphuric acid is added, stop and allow to cool before more sulphuric acid is added to the electrolyte. With the exception of lead or lead-lined containers, always use non-metallic receptacles or funnels. Do not store acid in excessively warm locations or in direct sunlight.

- Always wear suitable personnel protective equipment:

- Due to their hazardous contents, the disposal of startup and auxiliary batteries is strictly controlled. When a startup or auxiliary battery is scrapped, make sure that it is disposed of safely, complying with local environmental regulations. If in doubt, contact your local authority for advice on disposal facilities.

4. BATTERY CARE REQUIREMENTS

4.1 RECEIPT OF A NEW VEHICLE

Within 72 hours of receipt of a new vehicle, a battery condition check must be done in accordance with the battery test process utilizing a Jaguar Land Rover (JLR) approved tester. See the 'EQUIPMENT' section (section 5 of this procedure).

NOTES:

- The Midtronics software can be updated. Refer to administration bulletins to make sure that the EXP-1080, GRX-3080 and GR1-3080 are up-to-date.

- Midtronics WiFi dongles are mandated. Refer to special tool release notes titled 'Wi-Fi pod upgrade to the EXP-1080 battery tester'. Make sure that the dongles are installed at all times for the system to work correctly.

- The Midtronics code from the tester must be recorded on the form.

Any actions must be done in accordance with the 'Battery Tester Result Table' (section 6 of this procedure). The details must be recorded on the 'New Vehicle Storage Form' which is part of the 'New Vehicle Storage' document.

For additional information, refer to:New Vehicle Storage Form (100-11, Description and Operation).

4.2 NEW VEHICLE STORAGE

If the vehicle is to be stored, transport mode must be programed into the vehicle with the transit relay installed as delivered. Certain vehicles do not have a transit relay installed, these vehicles only need transport mode installed. For additional information, refer to the Transit Relay Installation Summary table (section 1 of this procedure) for transit relay installation.

Transit relay removal/vehicle placed in normal mode, should only be completed a maximum of 72 hours prior to handover to customer.

For vehicles without either a transit mode or transit relay, the negative cable must be disconnected from the startup battery.

The startup battery must be tested every 30 days and re-charged if required, in accordance with the battery test process utilizing a Jaguar Land Rover (JLR) approved tester. See the 'EQUIPMENT' section (section 5 of this procedure).

NOTES:

- Transport mode is required to be set when a transit relay is installed to a vehicle to prevent damage to vehicle electrical modules.

- The Midtronics code from the tester must be recorded on the form.

Any actions must be done in accordance with the Battery Tester Result Table (section 6 of this procedure). The details must be recorded on the 'New Vehicle Storage Form' which is part of the 'New Vehicle Storage' document.

For additional information, refer to:New Vehicle Storage Form (100-11, Description and Operation).

4.3 PRE-DELIVERY INSPECTION/DELIVERY TO THE CUSTOMER

Before the vehicle is handed over to the customer and as part of the Pre-Delivery Inspection (PDI), the condition of the battery needs to be confirmed. The battery condition must be checked in accordance with the battery test process utilizing a Jaguar Land Rover (JLR) approved tester. See the 'EQUIPMENT' section (section 5 of this procedure).

NOTE:

The Midtronics code from the tester must be recorded on the form.

Any actions must be done in accordance with the 'Battery Tester Result Table' (Section 6 of this procedure). The details must be recorded on the 'New Vehicle Storage Form' which is part of the 'New Vehicle Storage' document.

For additional information, refer to:New Vehicle Storage Form (100-11, Description and Operation).

4.4 REPLACEMENT LEAD ACID BATTERIES FOR SERVICE

All service replacement startup and auxiliary batteries must have the battery condition checked within 24 hours of receipt and controlled on a ‘First In First Out’ basis. This makes sure that the batteries are not allowed to age unnecessarily.

For startup and auxiliary batteries in storage and not yet installed to a vehicle, they must be stored:

- In a cool/dry environment.

- Not in direct sunlight.

- Not near a direct heat source.

Any startup or auxiliary batteries that show any forms of damage or corrosion must not be installed to any vehicle. Any startup or auxiliary batteries which are dropped must be scrapped, this applies even if no external damage is apparent.

The startup and auxiliary batteries must be tested every 30 days and re-charged if required, in accordance with the battery test process utilizing a Jaguar Land Rover (JLR) approved tester. See the 'EQUIPMENT' section (section 5 of this procedure).

Any actions must be done in accordance with the 'Battery Tester Result Table' (section 6 of this procedure). The details must be recorded on the 'Battery Care Sheet'.

For additional information, refer to:Battery Care Sheet (414-00, Description and Operation).

4.5 LEAD ACID BATTERY INSTALLED IN VEHICLE MAINTENANCE

The startup battery must be tested every 30 days and re-charged if required, in accordance with the battery test process utilizing a Jaguar Land Rover (JLR) approved tester. See the 'EQUIPMENT' section (section 5 of this procedure).

The startup battery must always be connected to a battery support unit during any diagnostic sessions, including software updates.

For additional information, refer to:Battery Support Unit Connection Procedure (414-00, General Procedures).

4.6 LEAD ACID BATTERY TEST

Enhancement to the recommended battery test equipment software, has removed the need to physically remove lead acid battery surface charge before completing a battery test.

The battery may be tested either on a bench or on the vehicle.

NOTE:

Make sure the ignition is off and the vehicle is powered down with the modules entering 'sleep mode' before commencing the battery test.

Lead Acid Battery Test Types

Flooded Lead Acid Battery Testing

In some markets serviceable flooded startup batteries are used. Before any testing of the startup battery is done, check the electrolyte level. Refer for details in the 'CONFIRMING ELECTROLYTE LEVEL' (section 9 in this procedure).

All AGM and Flooded Lead Acid Battery Testing

The Jaguar Land Rover (JLR) recommended battery tester has 3 types of battery tests available for the technician to select:

>td rowspan="1">2>td rowspan="1">3

| NUMBER | TEST NAME | WHEN TO BE USED | BATTERY STATUS |

|---|---|---|---|

| 1 | BATTERY TEST | Any startup battery that has started its warranty life cycle. | |

| PDI/STORAGE | Any startup battery or auxiliary battery that has not yet been entered into the warranty life cycle. | ||

| BATT. STORAGE | Any startup battery or auxiliary battery that has not yet been entered into the warranty life cycle. | The startup battery or auxiliary battery is not in use and is a parts stock battery and has not yet been installed to a vehicle. |

NOTE:

When 'BATT. STORAGE' is selected, the technician must enter identification data or a purchase order reference number for the battery being tested.

The startup/auxiliary battery condition must be checked in accordance with the battery test process utilizing a Jaguar Land Rover (JLR) approved tester. See the 'EQUIPMENT' section (section 5 of this procedure).

NOTE:

The Midtronics code from the tester must be recorded on the form.

Any actions must be done in accordance with the 'Battery Tester Result Table' (section 6 of this procedure). The details must be recorded on the 'New Vehicle Storage Form' which is part of the 'New Vehicle Storage' document.

For additional information, refer to:New Vehicle Storage Form (100-11, Description and Operation).

CAUTION:

Do not connect the tester to any other circuit or chassis point other than the battery negative terminal.

5. EQUIPMENT

All equipment used must be functionally capable of meeting the compliance requirements. Please refer to the approved equipment document (JLR 000015).

In the case of startup or auxiliary batteries installed to a new vehicle at the retailer, battery condition should be measured using the appropriate hand-held Midtronics tester as follows:

| LEAD ACID BATTERY TYPE | BATTERY TESTER | BATTERY TESTER AND CHARGER |

|---|---|---|

| Absorbed Glass Mat (AGM) and flooded |

|

|

The test results must be recorded on the 'New Vehicle Storage Form' which is part of the 'New Vehicle Storage' document.

For additional information, refer to:New Vehicle Storage Form (100-11, Description and Operation).

NOTE:

All equipment must be calibrated.

6. DETERMINING BATTERY CONDITION

Battery Tester Result Table

| BATTERY TESTER RESULTS | ACTION |

|---|---|

| GOOD BATTERY | Return the startup or auxiliary battery to service. |

| CHARGE AND RE-TEST |

|

| REPLACE BATTERY OR BAD CELL BATTERY |

|

| UNABLE TO DO TEST | Disconnect the startup or auxiliary battery from the vehicle and test again. |

7. BATTERY CHARGING

It is essential that a suitably ventilated defined area exists in each retailer for startup and auxiliary battery charging.

CAUTION:

It is very important that when charging batteries for diagnostic charging please follow the below links:

GR8-1180: For additional information, refer to:Battery Diagnostics - 12 Volt Midtronics GR8-1180 JLR Diagnostic Battery Charger (414-01, Diagnosis and Testing).

GRX-3080: For additional information, refer to:Battery Diagnostics - 12 Volt Midtronics GRX-3080 JLR Diagnostic Battery Charger (414-01, Diagnosis and Testing).

CAUTION:

For all other Jaguar Land Rover (JLR) approved chargers, follow the manufacturers operating instructions. When using the traction charger or other standalone chargers make sure that the charger is set for the correct type of battery before charging commences. If the wrong switch is selected the result would be a battery that is not charged fully and/or overheating can occur.

The battery must be tested every 30 days and re-charged if required, in accordance with the battery test process utilizing a Jaguar Land Rover (JLR) approved tester. See the 'EQUIPMENT' section (section 5 of this procedure). It is recommended that retailers always have fully charged startup batteries ready for use.

CAUTION:

Do not charge Absorbed Glass Mat (AGM) batteries with more than 14.8V, as this will damage the startup battery.

A designated controlled area must be allocated for scrap batteries and clearly controlled as such.

To bring a discharged but serviceable battery back to a fully charged condition proceed as follows:

- Check and if necessary top up the startup battery electrolyte level. (maintainable flooded batteries only)

- Charge the startup or auxiliary battery using a Jaguar Land Rover (JLR) approved charger as detailed above.

NOTE:

The Midtronics code from the tester must be recorded on the form. Any actions must be done in accordance with the 'Battery Tester Result Table' (section 6 of this procedure). The details must be recorded on the 'New Vehicle Storage Form' which is part of the 'New Vehicle Storage' document.

For additional information, refer to:New Vehicle Storage Form (100-11, Description and Operation).

After charging the startup or auxiliary battery, a post charge battery condition test must be done in accordance with the Battery Tester Result Table (section 6 of this procedure).

NOTE:

The Midtronics code from the tester must be recorded on the form.

Any actions must be done in accordance with the Battery Tester Result Table (section 6 of this procedure). The details must be recorded on the 'New Vehicle Storage Form' which is part of the 'New Vehicle Storage' document.

For additional information, refer to:New Vehicle Storage Form (100-11, Description and Operation).

8. BATTERY REPLACEMENT

CAUTION:

Absorbed Glass Mat (AGM) and flooded batteries are not interchangeable, only the specified startup and auxiliary batteries must be used. Failure to follow this instruction will result in premature startup battery or auxiliary battery failure.

If it is determined that a startup battery or auxiliary battery (if equipped) requires replacement. Refer to the appropriate section of the workshop manual for instructions on removing and installing the startup or auxiliary battery from the vehicle.

On in service vehicles, the Battery Monitoring System (BMS) control module must be reset following the installation of a new startup battery. The BMS control module reset procedure must be done using the Jaguar Land Rover (JLR) approved diagnostic equipment.

9. CONFIRMING THE ELECTROLYTE LEVEL

WARNINGS:

- Before the startup battery electrolyte level is checked, refer to the 'HEALTH AND SAFETY PRECAUTIONS' (section 3 in this procedure).

- Absorbed Glass Mat (AGM) batteries are fully sealed for life and no attempt should be made to check or adjust the electrolyte level.

NOTES:

- In hot climates more frequent checks of the battery electrolyte level and condition are required. If necessary, the battery cells must be topped up using distilled water only.

- Only flooded startup batteries can have the electrolyte level topped up.

On certain flooded startup battery types the electrolyte level will need to be checked.

CAUTION:

Do not overfill the flooded startup battery cell with distilled water.

- Make sure the flooded startup battery is of a type suitable for topping up. These types of flooded startup batteries will have cell plugs visible on the top face of the startup battery or a removable access panel to allow access to the cells.

- On startup batteries with a clear or opaque case and level marks, check the electrolyte level by visual inspection of the maximum level indicator mark on the startup battery casing. The maximum level indicator mark indicates adequate electrolyte level above the startup battery separators.

- On startup batteries with black cases, remove the cell plugs or access panel and make sure that the electrolyte level is level with the indicator in the cell hole. A flashlight may be required to see the electrolyte level on the flooded startup battery.

- If the electrolyte level is low, top up using distilled water only.

- Refit the startup battery cell plugs.

- Charge the startup battery for 1 hour (60 minutes) using a recommended charger. If a GRX-3080 charger is used select manual charging for 1 hour (60 minutes).

- Do a battery test using the recommended test equipment. Refer to the Battery Test (section 4.6) and the 'EQUIPMENT' (section 5) in this procedure.

NOTE:

Maintenance free Absorbed Glass Mat (AGM) batteries are sealed and therefore cannot have the electrolyte topped up.