Range Rover Sport / L494 2017 FUEL CHARGING MANUAL

303-04A: Fuel Charging and Controls - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2

303-04B: Fuel Charging and Controls - Turbocharger - TDV6 3.0L Diesel

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2 (G1509429)

Torque Specification

A = refer to procedure for the correct torque sequence.

| DESCRIPTION | NM | LB-FT | LB-IN |

|---|---|---|---|

| Fuel injection pump cradle bolts | 3 | - | 26 |

| Fuel injection pump retaining bolts | 23 | 16 | - |

| Fuel injection pump bracket | 10 | - | 88 |

| Fuel injection pump sprocket bolt | 50 | 37 | - |

| Fuel injection pump belt rear cover retaining bolts | 10 | - | 88 |

| Camshaft rear end accessory drive (READ) pulley hub retaining bolt | A | - | - |

| Fuel injection pump belt tensioner retaining bolt | 23 | 16 | - |

| Camshaft READ pulley retaining bolt | A | - | - |

| Fuel injector retaining bolts | 9 | - | 80 |

| Fuel rail retaining bolts | 24 | 18 | |

| High-pressure fuel line bracket retaining bolts | 10 | - | 88 |

| High-pressure fuel line union nuts | A | - | - |

| Fuel rail supply tube union nuts | A | - | - |

| Fuel crossover line union nuts | A | - | - |

| Crankcase ventilation pipe retain bolts | 10 | - | 88 |

| Intake air shutoff valve retaining nut | 10 | - | 88 |

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2 (G1781152)

| ITEM | DESCRIPTION |

|---|---|

| 1 | Fuel Rail Pressure (FRP) sensor |

| 2 | Fuel rail - Bank 1 |

| 3 | High Pressure (HP) fuel pump - with internal transfer pump |

| 4 | Fuel rail - Bank 2 |

| 5 | Fuel rail Pressure Control Valve (PCV) |

| 6 | Fuel injector (6 off) |

The TDV6 3.0L diesel engine is equipped with a High Pressure (HP) common rail fuel injection system. With this fuel injection process, a HP fuel pump delivers a uniform level of pressure to the shared fuel lines (the fuel rails), which serve all 6 fuel injectors. Pressure is controlled to the optimum level for smooth operation.

The common rail system supports a pre and pilot injection depending on engine operating conditions, which reduces combustion noise levels, more commonly referred to as 'diesel knock'.

Fuel injection pressure is generated independently of engine speed and fuel injection events.

The fuel injection timing and volume are calculated by the Engine Control Module (ECM), which then energizes the appropriate piezo actuated injector.

The common rail fuel injection system has the following features:

- High fuel injection pressures of up to 2000 bar (29007 lbf/in²) for greater atomization of fuel (increasing performance and lowering emissions)

- Variable injection to optimize combustion in all engine operating conditions

- Low tolerances and high precision throughout the life of the system.

The system features the following components:

- HP fuel pump

- Fuel rails

- HP and Low Pressure (LP) fuel pipes

- Fuel injectors.

HIGH PRESSURE (HP) FUEL PUMP

| ITEM | DESCRIPTION |

|---|---|

| 1 | Low Pressure (LP) fuel return connection |

| 2 | Low Pressure (LP) fuel supply connection |

| 3 | Fuel temperature sensor |

| 4 | Drive shaft |

| 5 | Fuel outlet to Bank 2 fuel rail |

| 6 | Fuel metering valve |

| 7 | Fuel outlet to Bank 1 fuel rail |

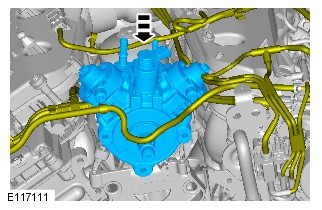

The HP fuel pump is a 2 piston radial plunger pump. The pump has the ability to produce a maximum pressure of 2000 bar (29007 lbf/in²).

The HP fuel pump is driven from the Bank 2 cylinder head exhaust camshaft via a toothed belt. The drive from the belt rotates a cam within the pump which operates a plunger within each pumping element. A procedure and special tools are required for pump or belt replacement to time the pump. For additional information, refer to:Engine (303-01A Engine - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation) / Engine (303-01 Engine - SDV6 3.0L Diesel - Hybrid Electric Vehicle, Description and Operation) / Fuel Pump (303-04A Fuel Charging and Controls - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

The HP fuel pump comprises 2 HP pumping elements, a fuel metering valve, an internal transfer pump and a fuel temperature sensor.

The fuel is delivered to the internal transfer pump via the external fuel filter and an electric fuel pump which is located in the fuel tank. For additional information, refer to:Fuel Tank and Lines (310-01A Fuel Tank and Lines - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation).

The fuel metering valve is located in the feed port between the HP pumping elements and the internal transfer pump. The fuel metering valve is a variable position solenoid-operated valve that is controlled by the ECM. The fuel metering valve determines the amount of fuel that is delivered from the internal transfer pump to the HP pumping elements. When there is no signal to the fuel metering valve, the valve is closed and there is no fuel delivery.

The fuel from the internal transfer pump is passed to the HP pumping elements at a constant pressure known as transfer pressure. The transfer pressure is controlled by an internal Pressure Relief Valve (PRV). Once the fuel enters each of the HP pumping elements the pressure rises rapidly, with each element providing a HP supply to one of the fuel rails. The pressure is controlled by the fuel rail Pressure Control Valve (PCV) and the Fuel Rail Pressure (FRP) sensor.

A controlled amount of fuel is allowed to leak-off from the internal transfer pump. This fuel cools and lubricates the internal components of the HP fuel pump, then returns to the fuel tank through the Low Pressure (LP) fuel return line.

The fuel temperature sensor is located on the rear of the HP fuel pump. It measures the fuel temperature in the LP side of the HP fuel pump. The ECM continually monitors this signal to determine the fuel temperature to prevent overheating of the fuel system. The ECM will also make fine adjustments to fuel injection quantity to adjust for fuel temperature.

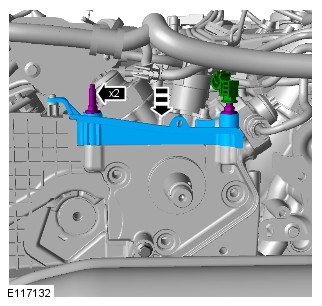

FUEL RAILS

| ITEM | DESCRIPTION |

|---|---|

| 1 | Fuel rail balance pipe |

| 2 | Supply pipe to Bank 1 fuel rail |

| 3 | Supply pipe to Bank 2 fuel rail |

| 4 | Fuel rail - Bank 2 |

| 5 | Fuel Pressure Control Valve (PCV) |

| 6 | Supply pipe to fuel injector (6 off) |

| 7 | Fuel Rail Pressure (FRP) sensor |

| 8 | Fuel rail - Bank 1 |

| ITEM | DESCRIPTION |

|---|---|

| 1 | High Pressure (HP) fuel pump fuel return tube |

| 2 | Bank 2 fuel injector leak-back tube |

| 3 | Fuel rail Pressure Control Valve (PCV) fuel return tube |

| 4 | Fuel return connection to fuel cooler |

| 5 | Bank 1 fuel injector leak-back tube |

Two fuel rails are used with each rail supplying high pressure fuel to 3 fuel injectors.

Each rail has 5 threaded connections which provide for the attachment of the high pressure fuel supply from the HP fuel pump, the balance pipe and connections for the 3 injectors supplied with fuel from that rail.

The fuel pressure in the rails is detected by the FRP sensor which is located in the front of the Bank 1 fuel rail. The Bank 2 fuel rail houses a fuel rail PCV. The ECM controls the fuel rail PCV using signals from the FRP sensor. Fuel released by the fuel rail PCV flows into the LP fuel return line.

The FRP sensor is a piezo-resistive type sensor containing an actuating diaphragm. Deflection of the diaphragm provides a proportional signal (output) voltage to the ECM, dependant on the fuel pressure within the fuel rail.

Both rails are connected together with a balance pipe which ensures the pressure in both rails is equal, even though each rail is supplied from a different pumping element in the HP fuel pump.

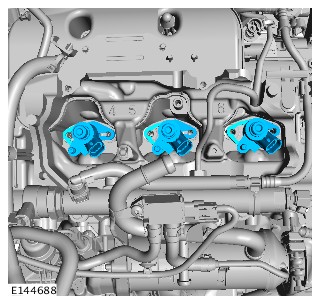

FUEL INJECTORS

| ITEM | DESCRIPTION |

|---|---|

| 1 | Fuel return |

| 2 | O-ring seal |

| 3 | Piezo stack actuator |

| 4 | Hydraulic coupler |

| 5 | Control valve |

| 6 | Nozzle body |

| 7 | Copper sealing washer |

| 8 | Electrical connector |

| 9 | High Pressure (HP) feed |

| 10 | Nozzle |

Each injection event is controlled by a charge and discharge cycle allowing energy to dissipate in, and recover from, the injector. Never disconnect the wiring connector when the vehicle is running. The injector may remain open thus causing engine damage.

Six fuel injectors are used in the fuel system. A piezo actuator in each injector is electronically controlled by the ECM to operate the injector in response to engine speed and load conditions.

Each injector has an electrical connector which connects the injector to the engine harness. A fuel connection on the top of the injector provides for the high pressure fuel inlet from the related fuel rail. A second fuel connection allows fuel leakage within the injector to drain into the LP fuel return line.

Each injector is located in a machined hole in the cylinder head and is sealed in the cylinder head with a copper sealing washer and an O-ring seal. The injector is retained in the cylinder head with a clamp plate and 2 bolts. If an injector is removed or replaced, a new copper sealing washer and a clamp plate must be used when refitting the injector.

The injector can operate up to 5 times during one combustion cycle depending on engine speed and load. The injection sequence can occur as follows:

- Pilot injection - occurs before the main injection and improves fuel and air mixing

- Pre-injection - shortens the main injection's ignition delay and therefore reduces the generation of nitrous oxides

- Main injection - delivers the required engine torque

- After injection - occurs after the main injection and assists the re-burn of any remaining particulate matter

- Post injection - helps manage the temperature of the exhaust gas for more effective exhaust-gas after-treatment

- Injection delay 0.4 ms.

Each injector is calibrated to the ECM and applicable cylinder to which it is fitted. Therefore, if an injector is removed it must be refitted to the cylinder from which it was removed. If a new injector is fitted, a calibration routine using Land Rover approved diagnostic equipment must be performed to calibrate the injector unique code to the ECM.

The operating voltage of the injector is between 110 and 163 volts depending on engine speed and load and care must be taken when working in the vicinity of the injectors. The pressure increases linearly from 200 to 1200 bar (2900 to 17404 lbf/in²).

Each injector has an electrical resistance value of between 150 - 250 kOhms.

ENGINE STARTING

During starting, the fuel rail pressure must be at least 120 bar (1740 lbf/in²). Should the pressure be below this figure, the injectors will not operate, resulting in the vehicle not starting.

ENGINE STOPPING

To stop the engine the ECM stops energizing the actuators in the fuel injectors, therefore, no fuel is injected and the engine speed drops to zero. For additional information, refer to:Electronic Engine Controls (303-14A Electronic Engine Controls - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation) / Electronic Engine Controls (303-14 Electronic Engine Controls - SDV6 3.0L Diesel - Hybrid Electric Vehicle, Description and Operation).

HP FUEL PUMP

When the HP fuel pump is rotated, pressure is created when the fuel metering valve is open and the fuel rail PCV is closed. Both valves are electronically controlled by the ECM to allow variable fuel delivery and pressure control. When the ECM actuates the fuel injectors, the fuel rail pressure drop is off-set by additional fuel being delivered to the fuel rails by the fuel rail PCV. The fuel pressure in the system is reduced within a few seconds after the engine has stopped as the fuel rail PCV no longer has the holding current it requires, and therefore opens. No residual pressure remains in the system and the fuel is released into the LP fuel return line through the open fuel rail PCV.

A = Hardwired.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Battery |

| 2 | Battery Junction Box 2 (BJB2) |

| 3 | Battery Junction Box (BJB) |

| 4 | Auxiliary Junction Box (AJB) |

| 5 | Engine Junction Box (EJB) |

| 6 | Central Junction Box (CJB) |

| 7 | Engine Control Module (ECM) |

| 8 | Fuel injector (6 off) |

| 9 | Fuel temperature sensor |

| 10 | Fuel metering valve |

| 11 | Fuel Rail Pressure (FRP) sensor |

| 12 | Fuel rail Pressure Control Valve (PCV) |

Diagnosis and Testing

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2 (G2718609)

For a detailed description of the fuel charging and controls system and operation, refer to the relevant Description and Operation section of the workshop manual. REFER to:Fuel Charging and Controls (303-04A Fuel Charging and Controls - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation).

Make sure that all suitable safety precautions are observed when carrying out any work on the fuel system. Failure to observe this warning may result in personal injury.

-

Make sure that absolute cleanliness is observed when working with these components. Always install blanking plugs to any open orifices or lines. Failure to follow this instruction may result in damage to the vehicle.

-

Diagnosis by substitution from a donor vehicle is NOT acceptable. Substitution of control modules does not guarantee confirmation of a fault and may also cause additional faults in the vehicle being checked and/or the donor vehicle.

Check and rectify basic faults before beginning diagnostic routines involving pinpoint tests.

- Verify the customer concern.

- Visually inspect for obvious signs of mechanical or electrical damage.

Visual Inspection

| MECHANICAL | ELECTRICAL |

|---|---|

|

|

- If an obvious cause for an observed or reported concern is found, correct the cause (if possible) before proceeding to the next step.

- If the cause is not visually evident, verify the symptom and refer to the Symptom Chart, alternatively check for Diagnostic Trouble Code(s) (DTC)s and refer to the DTC Index.

| SYMPTOM | POSSIBLE CAUSES | ACTION |

|---|---|---|

| Engine cranks, but does not start |

|

Check that the inertia switch has not tripped. Check the fuel level and condition. Draw off approximately 1 ltr (2.11 pints) of fuel and allow to stand for 1 minute. Check to make sure there is no separation of the fuel indicating water or other liquid in the fuel. Check the intake air system for leaks. Check the fuel pump operation, check the low-pressure fuel system for leaks/damage. Check the fuel filter, check for DTCs indicating a fuel volume or pressure control valve fault. Check the fuel pump. Check the CKP circuits. Refer to the electrical guides. |

| Difficult to start |

|

Check the glow plug circuits. Refer to the electrical guides. Check the fuel level/condition. Draw off approximately 1 ltr (2.11 pints) of fuel and allow to stand for 1 minute. Check to make sure there is no separation of the fuel indicating water or other liquid in the fuel. Check the intake air system for leaks. Check the fuel pump operation, check the low-pressure fuel system for leaks/damage. Check the fuel filter, check for DTCs indicating a fuel volume or pressure control valve fault. Check the exhaust gas recirculation system. |

| Rough idle |

|

Check the intake air system for leaks. Check the fuel level/condition. Draw off approximately 1 ltr (2.11 pints) of fuel and allow to stand for 1 minute. Check to make sure there is no separation of the fuel indicating water or other liquid in the fuel. Check the low-pressure fuel system for leaks/damage. Check the fuel filter, check for DTCs indicating a fuel volume or pressure control valve fault. Check the exhaust gas recirculation system. |

| Lack of power when accelerating |

|

Check the intake air system for leakage or restriction. Check for a blockage/restriction in the exhaust system, install new components as necessary. Check for DTCs indicating a fuel pressure fault. Check the exhaust gas recirculation system. Check turbocharger actuator. |

| Engine stops/stalls |

|

Check the intake air system for leaks. Check the fuel level/condition. Draw off approximately 1 ltr (2.11 pints) of fuel and allow to stand for 1 minute. Check to make sure there is no separation of the fuel indicating water or other liquid in the fuel. Check the fuel system for leaks/damage: Check for DTCs indicating a fuel volume or pressure control valve fault. Check the exhaust gas recirculation system. |

| Engine judders |

|

Check the fuel level/condition. Draw off approximately 1 ltr (2.11 pints) of fuel and allow to stand for 1 minute. Check to make sure there is no separation of the fuel indicating water or other liquid in the fuel. Check the intake air system for leaks. Check the low-pressure fuel system for leaks/damage. Check the high pressure fuel system for leaks, check for DTCs indicating a fuel volume or pressure control valve fault. Check the fuel pump. |

| Excessive fuel consumption |

|

Check the low-pressure fuel system for leaks/damage. Check for DTCs indicating a fuel volume or pressure control valve fault. Check the fuel temperature sensor, fuel pump, etc for leaks. Check for injector DTCs. Check the exhaust gas recirculation system. |

Affected Vehicle Range

| MODEL: | MODEL YEAR: | VEHICLE IDENTIFICATION NUMBER (VIN): | ASSEMBLY PLANT: | APPLICABILITY: |

|---|---|---|---|---|

| Range Rover (LG) | 2015-2019 | 214632-533162 | Solihull | TDV6 3.0L Diesel - Gen 2 |

| Range Rover Sport (LW) | 2015-2016 | 518538-599999 | Solihull | TDV6 3.0L Diesel - Gen 2 |

| Range Rover Sport (LW) | 2015-2018 | 613794-699492 | Solihull | TDV6 3.0L Diesel - Gen 2 |

| Range Rover Sport (LW) | 2016-2018 | 100003-199996 | Solihull | TDV6 3.0L Diesel - Gen 2 |

| Range Rover Sport (LW) | 2018-2019 | 400291-421768 | Solihull | TDV6 3.0L Diesel - Gen 2 |

| Range Rover Sport (LW) | 2018-2019 | 800063-831586 | Solihull | TDV6 3.0L Diesel - Gen 2 |

| Range Rover Velar (LY) | 2018-2019 | 700002-799787 | Solihull | TDV6 3.0L Diesel |

| Discovery (LR) | 2017-2019 | 000001-090164 | Solihull | TDV6 3.0L Diesel |

The MIL is illuminated on the IPC with DTC P0234-77 stored in the Powertrain Control Module (PCM) which may be accompanied with DTCs P2463-00 and P246B-00.

Component failure.

Follow the instructions below.

| DESCRIPTION | QUANTITY |

|---|---|

| Intake air shutoff throttle | 1 |

| Inlet hose clamp | 1 |

16 Model Year (MY) vehicles and earlier

This procedure requires a minimum of SDD 158.04 and Software Management Pack 329 loaded or later.

-

The JLR approved diagnostic equipment will read the VIN for the vehicle and automatically take the vehicle out of ‘Transportation mode’ if required.

-

All ignition ON/OFF instructions must be followed. Failure to complete these instructions may cause damage to the vehicle control modules.

- Connect the JLR approved battery support unit.

- Connect the JLR approved diagnostic equipment to the vehicle and begin a new session.

- Follow the JLR approved diagnostic equipment prompts.

- Using the JLR approved diagnostic equipment read the DTCs.

- If DTC P0234-77 is stored, continue to the 'Service Instruction A'.

- If DTC P0234-77 is not stored, do not continue with this procedure, continue diagnosis of the concern (see TOPIx Workshop Manual section 100-00: General Information - Description and Operation).

- When all of the tasks are complete, exit the session.

17 Model Year (MY) vehicles and later

This procedure requires Pathfinder version 259 loaded or a later version.

-

The JLR approved diagnostic equipment will read the VIN for the vehicle and automatically take the vehicle out of ‘Transportation mode’ if required.

-

All ignition ON/OFF instructions must be followed. Failure to complete these instructions may cause damage to the vehicle control modules.

- Connect the JLR approved battery support unit.

- Connect the JLR approved diagnostic equipment to the vehicle and begin a new diagnostic session.

- Follow the JLR approved diagnostic equipment prompts.

- Select 'ECU Diagnostics'.

- Select 'All DTCs'.

- If DTC P0234-77 is stored, continue to the 'Service Instruction A'.

- If DTC P0234-77 is not stored, do not continue with this procedure, continue diagnosis of the concern (see TOPIx Workshop Manual section 100-00: General Information - Description and Operation).

- When all of the tasks are complete, exit the session.

The DTC P0234-77 can be attributed to a leak in the air intake system.

- Complete a leakage test on the intake system using smoke test equipment (see TOPIx Workshop Manual section 303-12: Engine system general information - General procedures - Leakage test using smoke test equipment).

- If any leaks are found, repair as required referring to TOPIx Workshop Manual and submit a separate warranty claim.

- If no leaks are found, continue to 'Service Instruction B'.

- If any leaks have been rectified complete DTC read and clear, continue to step 4 for 16 MY vehicles and earlier or step 13 for 17 MY vehicles and later.

16 Model Year (MY) vehicles and earlier

This procedure requires a minimum of SDD 158.04 and Software Management Pack 329 loaded or later.

-

The JLR approved diagnostic equipment will read the VIN for the vehicle and automatically take the vehicle out of ‘Transportation mode’ if required.

-

All ignition ON/OFF instructions must be followed. Failure to complete these instructions may cause damage to the vehicle control modules.

- Connect the JLR approved battery support unit.

- Connect the JLR approved diagnostic equipment to the vehicle and begin a new session.

- Follow the JLR approved diagnostic equipment prompts.

- Using the JLR approved diagnostic equipment clear the DTCs.

- Complete a short vehicle road test.

- Using the JLR approved diagnostic equipment read the DTCs.

- If DTC P0234-77 is stored, continue to 'Service Instruction B'.

- If DTC P0234-77 is no longer stored, complete a dynamic regeneration using the diagnostic procedures below.

- If required, reset the vehicle to ‘Transportation mode’.

- When all of the tasks are complete, exit the session.

- Disconnect the JLR approved diagnostic equipment and the JLR approved battery support unit.

17 Model Year (MY) vehicles and later

This procedure requires Pathfinder version 259 loaded or a later version.

-

The JLR approved diagnostic equipment will read the VIN for the vehicle and automatically take the vehicle out of ‘Transportation Mode’ if required.

-

All ignition ON/OFF instructions must be followed. Failure to complete these instructions may cause damage to the vehicle control modules.

- Connect the JLR approved battery support unit.

- Connect the JLR approved diagnostic equipment to the vehicle and begin a new diagnostic session.

- Follow the JLR approved diagnostic equipment prompts.

- Select 'ECU Diagnostics'.

- Select 'All DTCs'.

- Select 'Clear all DTCs'.

- Complete a short vehicle road test.

- Select 'ECU Diagnostics'.

- Select 'All DTCs'.

- If DTC P0234-77 is stored, continue to the 'Service Instruction B'.

- If DTC P0234-77 is no longer stored, complete a dynamic regeneration using the diagnostic procedures below.

- Follow all on-screen instructions to complete this task.

- When all of the tasks are complete, exit the current session.

- Disconnect the JLR approved diagnostic equipment and the Jaguar Land Rover approved battery support unit.

Vehicles affected by this procedure are equipped with the Low Pressure (LP) Exhaust Gas Recirculation (EGR) system.

- Renew the intake air shutoff throttle (see TOPIx Workshop Manual section 303-04: Fuel Charging and Controls - Removal and Installation - Intake Air Shutoff Throttle).

- After installing a new intake air shut off throttle complete routine - Initialise Throttle Valve Actuator Learning 0x4030

- Complete a dynamic regeneration using the diagnostic procedures below.

16 Model Year (MY) vehicles and earlier

This procedure requires a minimum of SDD 158.04 and Software Management Pack 329 loaded or later.

-

The JLR approved diagnostic equipment will read the VIN for the vehicle and automatically take the vehicle out of ‘Transportation mode’ if required.

-

All ignition ON/OFF instructions must be followed. Failure to complete these instructions may cause damage to the vehicle control modules.

- Connect the JLR approved battery support unit.

- Connect the JLR approved battery support unit.

- Connect the JLR approved diagnostic equipment to the vehicle and begin a new session.

- Follow the JLR approved diagnostic equipment prompts.

- Click here to run: Diesel particulate filter dynamic regeneration (158.04 / 73670)

- If the hyperlink is not available, the application can be found as follows:

- Select the 'Service Functions’ Session Type

- Run 'Diesel particulate filter dynamic regeneration'

- If required, reset the vehicle to ‘Transportation mode’.

- When all of the tasks are complete, exit the session.

- Disconnect the JLR approved diagnostic equipment and the JLR approved battery support unit.

17 Model Year (MY) vehicles and later

This procedure requires Pathfinder version 259 loaded or a later version.

-

The JLR approved diagnostic equipment will read the VIN for the vehicle and automatically take the vehicle out of ‘Transportation mode’ if required.

-

All ignition ON/OFF instructions must be followed. Failure to complete these instructions may cause damage to the vehicle control modules.

- Connect the JLR approved battery support unit.

- Connect the JLR approved diagnostic equipment to the vehicle and begin a new diagnostic session.

- Follow the JLR approved diagnostic equipment prompts.

- Select 'Service'.

- Select 'Powertrain Control Module [PCM]: Diesel particulate filter dynamic regeneration'.

- Follow all on screen instructions to complete this task.

- If required, reset the vehicle to ‘Transportation mode’.

- When the task is completed, exit the session.

- Disconnect the JLR approved diagnostic equipment and the JLR approved battery support unit.

For a list of Diagnostic Trouble Codes that could be set on this vehicle, please refer to Section 100-00. REFER to:Diagnostic Trouble Code Index - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, DTC: Powertrain Control Module B10A2-07 to P02D7-32 (100-00 General Information, Description and Operation).

General ProceduresFUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

FUEL INJECTION COMPONENT CLEANING (G871913)

- 19.50.22

- FUEL INJECTION COMPONENT CLEANING USING A VACUUM GUN

- 3000 CC, TDV6

- 0.10

- USED WITHINS

-

Do not carry out any repairs to the fuel system with the engine running. The fuel pressure within the system can be as high as 1700 bar (24,656 lb-sq-in). Failure to follow this instruction may result in personal injury.

-

Do not smoke or carry lighted tobacco or open flame of any type when working on or near any fuel related components. Highly flammable vapors are always present and may ignite. Failure to follow these instructions may result in personal injury.

-

If fuel contacts the eyes, flush the eyes with cold water or eyewash solution and seek immediate medical attention.

-

Place the vehicle in a well ventilated, quarantined area and arrange ' No Smoking/Petrol Fumes' signs about the vehicle.

-

Wait at least 30 seconds after the engine stops before commencing any repair to the high-pressure fuel injection system. Failure to follow this instruction may result in personal injury.

-

Wash hands thoroughly after fuel handling, as prolonged contact may cause irritation. Should irritation develop, seek medical attention.

-

Do not carry or operate cellular phones when working on or near any fuel related components. Highly flammable vapors are always present and may ignite. Failure to follow these instructions may result in personal injury.

-

Before using the cleaning fluid, protect all electrical components and connectors with lint-free non-flocking material.

-

Make sure that all parts removed from the vehicle are placed on the lint-free non-flocking material.

-

Make sure that any protective clothing worn is clean and made from lint-free non-flocking material.

-

Make sure that clean non-plated tools are used. Clean tools using a new brush that will not lose its bristles and fresh cleaning fluid, prior to starting work on the vehicle.

-

Use a steel topped workbench and cover it with clean, lint-free non-flocking material.

-

Make sure the workshop area in which the vehicle is being worked on is as clean and as dust free as possible. Foreign matter from work on clutches, brakes or from machining or welding operations can contaminate the fuel system and may result in later malfunction.

Pneumatic vacuum gun

- Using a new brush that will not lose its bristles, brush cleaning fluid onto the components being removed and onto the surrounding area.

- Using a pneumatic vacuum gun, remove all traces of cleaning fluid and foreign material.

- Dispose of any used cleaning fluid and the brush after completing the repair.

Removal and Installation

UEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

LEFT FUEL INJECTORS (G1509431)

- 19.60.09

- INJECTORS - LH BANK SET - RENEW

- 3000 CC, TDV6

- 2.20

- USED WITHINS

SPECIAL TOOL(S)

100-012

Slide Hammer

310-213

Fuel Injector Removal Adapter

PART(S)

| STEP | PART NAME | QUANTITY |

|---|---|---|

| Installation Step 2 | Fuel injector seals | 1 |

| Installation Step 2 | Fuel injector washer(s) | 1 |

| Installation Step 5 | Fuel injector high pressure pipe(s) | 1 |

Diesel fuel injection equipment is manufactured to very precise tolerances and fine clearances. It is therefore essential that absolute cleanliness is observed when working with these components. Always install new blanking plugs to any open orifices or lines. Failure to follow this instruction may result in foreign matter ingress to the fuel injection system.

-

Some variation in the illustrations may occur, but the essential information is always correct.

-

Refurbished fuel injector leak off connector color does not denote the fuel injector flow characteristics. Only the refurbished part number is to be used to identify the type of injector.

-

Refer to:Fuel Injection Component Cleaning (303-04E Fuel Charging and Controls - TDV8 4.4L Diesel, General Procedures).

-

Refer to:Specifications (414-00 Battery and Charging System - General Information, Specifications).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

-

Refer to:Cooling System Partial Draining and Vacuum Filling (303-03A Engine Cooling - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, General Procedures).

-

Refer to:Cooling System Partial Draining and Vacuum Filling (303-03A Engine Cooling - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, General Procedures).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

-

Refer to:Specifications (414-00 Battery and Charging System - General Information, Specifications).

- If a new unit is installed, configure using the approved diagnostic tool.

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

RIGHT FUEL INJECTORS (G1509432)

- 19.60.11

- INJECTORS - RH BANK SET - RENEW

- 3000 CC, TDV6

- 2.20

- USED WITHINS

SPECIAL TOOL(S)

100-012

Slide Hammer

310-213

Fuel Injector Removal Adapter

JLR-310-237

Remover, Fuel Injector

PART(S)

| STEP | PART NAME | QUANTITY |

|---|---|---|

| Installation Step 2 | Fuel injector seals | 1 |

| Installation Step 2 | Fuel injector washer(s) | 1 |

| Installation Step 5 | Fuel injector high pressure pipe(s) | 1 |

Diesel fuel injection equipment is manufactured to very precise tolerances and fine clearances. It is therefore essential that absolute cleanliness is observed when working with these components. Always install new blanking plugs to any open orifices or lines. Failure to follow this instruction may result in foreign matter ingress to the fuel injection system.

-

Some variation in the illustrations may occur, but the essential information is always correct.

-

Refurbished fuel injector leak off connector color does not denote the fuel injector flow characteristics. Only the refurbished part number is to be used to identify the type of injector.

-

Refer to:Fuel Injection Component Cleaning (303-04E Fuel Charging and Controls - TDV8 4.4L Diesel, General Procedures).

-

Refer to:Specifications (414-00 Battery and Charging System - General Information, Specifications).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

-

Refer to:Cooling System Partial Draining and Vacuum Filling (303-03F Engine Cooling - TDV8 4.4L Diesel, General Procedures).

-

CAUTIONS:

-

Be prepared to collect escaping fuel.

-

Before disconnecting or removing components, ensure the area around the joint faces and connections are clean. Plug open connections to prevent contamination.

-

LH illustration shown, RH is similar.

NOTE:Make sure that the fuel injector return line has a maximum of 8 uses.

-

-

Refer to:Cooling System Partial Draining and Vacuum Filling (303-03F Engine Cooling - TDV8 4.4L Diesel, General Procedures).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

-

Refer to:Specifications (414-00 Battery and Charging System - General Information, Specifications).

- If a new unit is installed, configure using the approved diagnostic tool.

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

FUEL PUMP (G1509433)

- 19.45.08

- FUEL PUMP - RENEW

- 3000 CC, TDV6

- 6.70

- USED WITHINS

SPECIAL TOOL(S)

303-1145/2

Remover, Camshaft Rear Pulley Bolt

310-138A

Holding Tool, Fuel Pump Pulley

310-139A

Holding Tool, Fuel Pump Pulley

JLR-303-1523

Remover/Installer, Camshaft Rear Pulley

PART(S)

| STEP | PART NAME | QUANTITY |

|---|---|---|

| Installation Step 6 | Camshaft sprocket bolt | 1 |

| Installation Step 16 | Left fuel rail supply pipe | 1 |

| Installation Step 16 | Right fuel rail supply pipe | 1 |

| Installation Step 19 | Fuel rail balance pipe | 1 |

| Installation Step 20 | Fuel rail supply pipe(s) | 1 |

-

Removal steps in this procedure may contain installation details.

-

Some variation in the illustrations may occur, but the essential information is always correct.

-

Refer to:Fuel Injection Component Cleaning (303-04E Fuel Charging and Controls - TDV8 4.4L Diesel, General Procedures).

-

Refer to:Rear End Accessory Drive (303-05A Accessory Drive - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:Crankcase Vent Oil Separator (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

CAUTION:

Failure to use special tool JLR-303-1523 might result in engine damage/failure.

Special Tool(s): JLR-303-1523

-

Special Tool(s): JLR-303-1523

-

Using the special tool, remove and discard the rear camshaft pulley retaining bolt.Special Tool(s): 303-1145/2

- Remove the special tools.

-

Special Tool(s): 310-139A

-

Special Tool(s): 310-138A

-

Special Tool(s): 310-139ATorque: 50Nm

-

Special Tool(s): JLR-303-1523Torque: 10Nm

-

Special Tool(s): JLR-303-1523

-

CAUTION:

Make sure the torque wrench setting procedure is followed correctly. Failure to follow this instruction may result in damage to the vehicle.

- Calculate the setting for the torque wrench:

- Stage 1: Multiply the required torque by the effective length of the torque wrench (1).

- Stage 2: Add the effective length of the special tool (2) to the effective length of the torque wrench.

- Stage 3: Divide the total of stage 1 by the total of stage 2.

- Stage 4: Set the torque wrench to the figure arrived at in stage 3.

-

CAUTION:

Make sure the torque wrench setting procedure is followed correctly. Failure to follow this instruction may result in damage to the vehicle.

- Using the special tool, install the camshaft rear pulley retaining bolt.

- Stage one: Tighten to 80 Nm (59 lb.ft).

- Stage two: Tighten a further 80 degrees.

- Remove the special tools.

-

Refer to:Crankcase Vent Oil Separator (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:Rear End Accessory Drive (303-05A Accessory Drive - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:High-Pressure Fuel System Bleeding (310-00 Fuel System - General Information, General Procedures).

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

LEFT FUEL RAIL (G2165648)

- 19.60.03

- FUEL RAIL - LH BANK - RENEW

- 3000 CC, TDV6

- 3.20

- USED WITHINS

PART(S)

| STEP | PART NAME | QUANTITY |

|---|---|---|

| Installation Step 1 | Fuel rail balance pipe | 1 |

| Installation Step 6 | Left fuel rail supply pipe | 1 |

| Installation Step 11 | Fuel injector high pressure pipe(s) | 3 |

Wait for a minimum of 1 minute after the engine has stopped before carrying out any repair to the fuel injection system.

Before disconnecting or removing components, ensure the area around the joint faces and connections are clean. Plug open connections to prevent contamination.

Some variation in the illustrations may occur, but the essential information is always correct.

- Disconnect the startup battery ground cable.

Refer to:Battery and Cables (414-01 Battery, Mounting and Cables, Description and Operation).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

-

Refer to:Cooling System Draining and Vacuum Filling (303-03A Engine Cooling - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, General Procedures).

-

NOTE:

This step is only required on vehicles fitted with twin turbochargers.

Refer to:Left Exhaust Gas Recirculation Valve Outlet Tube - TDV6 3.0L Diesel - Gen 1.5 (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:Left Exhaust Gas Recirculation Valve - TDV6 3.0L Diesel - Gen 2 (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:Fuel Injection Component Cleaning (303-04A Fuel Charging and Controls - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, General Procedures).

-

Refer to:Left Exhaust Gas Recirculation Valve - TDV6 3.0L Diesel - Gen 2 (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

NOTE:

This step is only required on vehicles fitted with twin turbochargers.

Refer to:Left Exhaust Gas Recirculation Valve Outlet Tube - TDV6 3.0L Diesel - Gen 1.5 (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:Cooling System Draining and Vacuum Filling (303-03A Engine Cooling - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, General Procedures).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

- Connect the startup battery ground cable.

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

RIGHT FUEL RAIL (G1509435)

- 19.60.05

- FUEL RAIL - RH BANK - RENEW

- 3000 CC, TDV6

- 2.90

- USED WITHINS

PART(S)

| STEP | PART NAME | QUANTITY |

|---|---|---|

| Installation Step 1 | Right fuel rail supply pipe | 1 |

| Installation Step 2 | Fuel rail balance pipe | 1 |

| Installation Step 10 | Fuel injector high pressure pipe(s) | 1 |

Some variation in the illustrations may occur, but the essential information is always correct.

-

Refer to:Specifications (414-00 Battery and Charging System - General Information, Specifications).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

-

Refer to:Cooling System Partial Draining and Vacuum Filling (303-03F Engine Cooling - TDV8 4.4L Diesel, General Procedures).

-

Refer to:Left Exhaust Gas Recirculation Valve Outlet Tube - TDV6 3.0L Diesel - Gen 1.5 (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:Fuel Injection Component Cleaning (303-04E Fuel Charging and Controls - TDV8 4.4L Diesel, General Procedures).

-

Refer to:Right Exhaust Gas Recirculation Valve Outlet Tube (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

-

Refer to:Cooling System Partial Draining and Vacuum Filling (303-03F Engine Cooling - TDV8 4.4L Diesel, General Procedures).

-

Refer to:Secondary Bulkhead Center Panel - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-02 Front End Body Panels, Removal and Installation).

-

Refer to:Specifications (414-00 Battery and Charging System - General Information, Specifications).

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

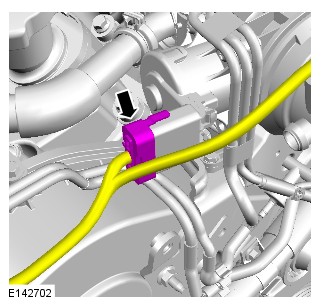

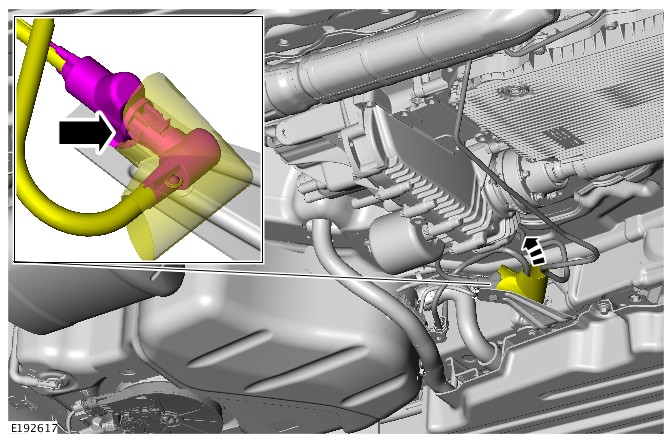

INTAKE AIR SHUTOFF THROTTLE (G1509436)

- 19.70.32

- THROTTLE - INTAKE AIR SHUT OFF - RENEW

- 3000 CC, TDV6

- 0.20

- USED WITHINS

PART(S)

| STEP | PART NAME | QUANTITY |

|---|---|---|

| Removal Step 8 | Exhaust gas recirculation outlet pipe to throttle body clamp | 1 |

| Removal Step 12 | Intake air shutoff throttle seals | 3 |

Removal steps in this procedure may contain installation details.

-

Refer to:Engine Cover - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2 (501-05 Interior Trim and Ornamentation, Removal and Installation).

-

NOTE:

If equipped.

Refer to:Left Exhaust Gas Recirculation Valve Outlet Tube - TDV6 3.0L Diesel - Gen 1.5 (303-08A Engine Emission Control - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

- To install, reverse the removal procedure.

- If a new unit is installed, configure using the approved diagnostic tool.

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

HIGH PRESSURE FUEL PUMP TEMPERATURE SENSOR (G2225219)

- 19.45.37

- HIGH PRESSURE FUEL PUMP TEMPERATURE SENSOR - RENEW

- 3000 CC, TDV6

- 6.70

- USED WITHINS

-

This procedure contains illustrations showing certain components removed to provide extra clarity.

-

This procedure contains some variation in the illustrations depending on the vehicle specification, but the essential information is always correct.

- Raise and support the vehicle on 2 post lift.

Refer to:Lifting (100-02 Jacking and Lifting, Description and Operation).

- Remove the High Pressure (HP) fuel pump.

Refer to:Fuel Pump (303-04A Fuel Charging and Controls - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

- Install the HP fuel pump.

Refer to:Fuel Pump (303-04A Fuel Charging and Controls - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Removal and Installation).

FUEL CHARGING AND CONTROLS - TDV6 3.0L DIESEL /TDV6 3.0L DIESEL - GEN 1.5/TDV6 3.0L DIESEL - GEN 2

FUEL PUMP DRIVER MODULE (G1605355)

- 19.45.11

- MODULE - FUEL PUMP CONTROL - RENEW

- ALL DERIVATIVES

- 0.20

- USED WITHINS

Removal steps in this procedure may contain installation details.

-

To install, reverse the removal procedure.NOTE:

If a new component has been installed, configure using Land Rover approved diagnostic equipment.

303-04B: Fuel Charging and Controls - Turbocharger - TDV6 3.0L Diesel

FUEL CHARGING AND CONTROLS - TURBOCHARGER - TDV6 3.0L DIESEL (G1509437)

Torque Specification

| DESCRIPTION | NM | LB-FT | LB-IN |

|---|---|---|---|

| Exhaust manifold retaining nuts | 28 | 21 | - |

| Turbocharger oil return tube to turbocharger retaining bolt | 9 | - | 80 |

| Turbocharger oil return tube to engine retaining bolt | 9 | - | 80 |

| Turbocharger bracket retaining bolts | 32 | 24 | - |

| Turbocharger to exhaust manifold retaining nuts | 24 | 18 | - |

| Exhaust manifold heatshield retaining bolt | 11 | 8 | - |

| Exhaust heatshield retaining bolt | 9 | - | 80 |

| Turbocharger oil supply tube union bolt | 30 | 22 | - |

| Exhaust gas recirculation (EGR) tube to EGR valve retaining bolts | 10 | - | 88 |

| EGR valve tube to exhaust manifold retaining bolts | 10 | - | 88 |

| Turbocharger bypass valve retaining bolts | 9 | 80 | |

| Turbocharger bypass valve to cross section duct bolts | 10 | 88 |

FUEL CHARGING AND CONTROLS - TURBOCHARGER - TDV6 3.0L DIESEL

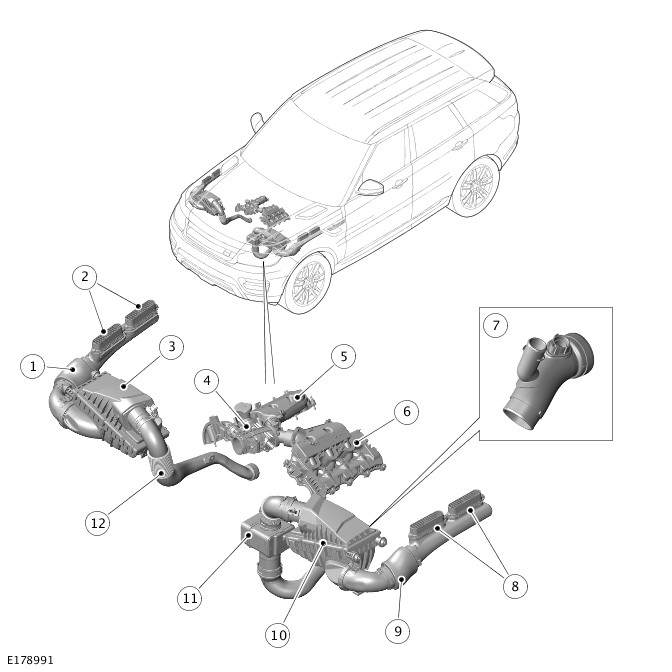

TURBOCHARGER (G1868446)

| ITEM | DESCRIPTION |

|---|---|

| 1 | Variable Geometry Turbine (VGT) turbocharger |

| ITEM | DESCRIPTION |

|---|---|

| 1 | Charge air intake valve |

| 2 | Turbine intake shut-off valve solenoid |

| 3 | Charge air solenoid |

| 4 | Variable Geometry Turbine (VGT) turbocharger - Primary |

| 5 | Vacuum reservoir |

| 6 | Fixed vane turbocharger - Secondary |

Depending on the market, the 3.0L V6 diesel engine is available in two variants. The single turbocharger variant uses a single VGT (Variable Geometry Turbine) type turbocharger, the twin turbocharger variant uses two turbochargers. The twin turbocharger variant comprises a VGT type turbocharger (primary turbocharger), and a fixed vane type (secondary turbocharger) turbocharger.

On the twin turbocharger variant, both turbochargers are used in a parallel sequential turbocharging system, which enables the engine to achieve quick throttle response at low engine speeds and efficient use of exhaust gas energy at high engine speeds. The primary turbocharger operates through the entire engine speed range, but is at its most efficient, at engine speeds of up to 2800 RPM it is running in a mono turbocharger mode. At engine speeds above 2800 RPM under load, the secondary turbocharger comes into operation, with both of the turbochargers running in a parallel bi-turbocharger mode.

The twin turbocharger system comprises the two turbochargers, the turbine intake shut-off valve solenoid, and the charge air intake valve, which incorporates the charge air recirculation solenoid and the charge air shut-off valve. The operation of the system is controlled by the ECM (Engine Control Module).

The turbochargers and the charge air intake valve are interconnected by the charge air ducts of the intake air distribution and filtering system. For additional information, refer to:Intake Air Distribution and Filtering (303-12A Intake Air Distribution and Filtering - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation).

Each turbocharger consists of two turbo elements, a turbine wheel and compressor wheel, enclosed separately in cast housings and mounted on a common shaft. The shaft in the primary turbocharger rotates in two ball bearings, however the secondary turbocharger comprises two semi-floating bearings which provides the shaft rotation.

The turbocharger bearings are lubricated and cooled by an oil supply from the cylinder block. The primary turbocharger has a connection for the engine cooling circuit to provide the appropriate cooling efficiency of the ball bearing. The primary turbocharger return oil drains into a dedicated area of the oil pan, assisted by an oil scavenge element in the vacuum pump. If fitted, the secondary turbocharger return oil drains into a dedicated area of the crankcase directly via drain tube. For additional information, refer to:Engine (303-01A Engine - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation).

VARIABLE GEOMETRY TURBINE (VGT) TURBOCHARGER - PRIMARY

| ITEM | DESCRIPTION |

|---|---|

| 1 | Charge air outlet |

| 2 | Exhaust inlet |

| 3 | Exhaust outlet |

| 4 | Oil feed connection |

| 5 | Coolant return connection |

| 6 | Coolant supply connection |

| 7 | Variable Geometry Turbine (VGT) vane actuator rod |

| 8 | Oil return connection |

| 9 | Variable Geometry Turbine (VGT) vane actuator |

| 10 | Clean air inlet |

The primary turbocharger is attached to the left exhaust manifold and secured to 3 studs on a flange on the manifold with nuts. On production, no gasket is used to seal the joint surface between the turbocharger and the manifold. In-service vehicles will require a service gasket to be fitted if the joint surface is disturbed.

A second flange on the turbocharger provides for the attachment of the left down pipe of the exhaust system. Three screws secure the down pipe to the flange and a gasket seals the joint.

The compressor end of the turbocharger has two hose connections. The central hose connection provides a clean air supply from the air cleaner to the compressor. The second connection on the outside of the housing provides for the attachment of the charge air ducts.

The turbocharger comprises a turbine wheel and a machined compressor wheel, sharing a common shaft which is supported on ball bearings. The application of the machined compressor wheel and the ball bearing results improved durability, reduced NVH (Noise, Vibration and Harshness) and optimized fuel economy. The turbocharger receives an engine oil feed via a pipe from the cylinder block. The pipe supplies the turbocharger with engine oil for lubrication purposes. An oil drain pipe from the turbocharger allows oil to drain from the turbocharger into the cylinder block. The turbocharger also has a connection for the engine cooling circuit to provide the appropriate cooling efficiency of the ball bearing.

An integral bracket houses the VGT vane actuator. The VGT vane actuator is connected to an eccentric lever which moves the turbine housing to adjust the position of the vanes. When the actuator operates a boss is rotated, which in turn moves the lever and changes rotary motion into linear motion. The lever is connected to a rod attached to the outside of the turbine housing and the linear motion is converted back to rotary motion of the housing.

Operation of the VGT vane actuator is controlled by the ECM. The VGT vane actuator also provides the ECM with a feedback signal to determine the pitch angle of the vanes.

The variable vanes in the turbocharger improve the exhaust gas power transfer to the turbine wheel which in turn drives the compressor wheel. This greatly assists the increase in charge air pressure at low engine speeds.

SECONDARY TURBOCHARGER (WHERE FITTED)

| ITEM | DESCRIPTION |

|---|---|

| 1 | Turbine intake shut-off valve |

| 2 | Exhaust intake |

| 3 | Oil feed connection |

| 4 | Seal pressurizing air pipe |

| 5 | Charge air outlet |

| 6 | Clean air intake |

| 7 | Compressor housing |

| 8 | Electrical connector - Turbine intake shut-off valve position sensor |

| 9 | Exhaust outlet |

| 10 | Vacuum connection |

| 11 | Turbine housing |

| 12 | Oil return connection |

The secondary turbocharger is attached to the right exhaust manifold and is secured to 3 studs on a flange on the manifold with nuts. On production, no gasket is used to seal the joint surface between the turbocharger and the manifold. In-service vehicles will require a service gasket to be fitted if the joint surface is disturbed.

A second flange on the turbocharger provides for the attachment of the right down pipe of the exhaust system. Two screws secure the down pipe to the flange and a gasket seals the joint.

The compressor end of the turbocharger has two hose connections. The central connection provides a clean air supply from the air cleaner to the compressor. The second connection on the outside of the housing provides for the attachment of the charge air ducts.

A pipe on the center housing of the turbocharger provides for the connection of a bleed air pipe from the charge air duct connection with the electric throttle. The bleed air is used to pressurize the seals of the compressor stage to prevent oil leaking into the compressor housing when the turbocharger is not running.

Attached to the rear of the turbocharger is a turbine intake shut-off valve operated by a vacuum actuator. The ECM operates the turbine intake shut-off valve solenoid to apply and release the vacuum in the actuator, which opens the turbine intake shut-off valve when a vacuum is present. The turbine intake shut-off valve is closed when the system is operating in mono-turbocharger mode, diverting exhaust gases from the right exhaust manifold, via the exhaust cross-over duct to the left exhaust manifold. A position sensor in the turbine intake shut-off valve allows the ECM to monitor the shut-off valve for correct operation.

CHARGE AIR INTAKE VALVE (WHERE FITTED)

| ITEM | DESCRIPTION |

|---|---|

| 1 | Charge air recirculation solenoid |

| 2 | Charge air shut-off valve connecting rod |

| 3 | Vacuum connection |

| 4 | Vacuum actuator |

| 5 | Charge air outlet connection (to charge air coolers) |

| 6 | Charge air shut-off valve body |

| 7 | Charge air recirculation solenoid body |

| 8 | Charge air intake (from secondary turbocharger) |

| 9 | Charge air recirculation solenoid outlet connection (to primary turbocharger clean air duct) |

The charge air intake valve is attached to a bracket on the front subframe and the cooling pack protector. The ECM uses the valve to control the bi-turbocharger operation of the turbochargers.

The charge air intake valve consists of a recirculation solenoid and a shut-off valve that are connected together by four screws and a gasket. The charge air recirculation solenoid controls the flow of air from the compressor of the secondary turbocharger to the clean air duct of the primary turbocharger. The charge air shut-off valve controls the flow of air from the compressor of the secondary turbocharger to the charge air coolers.

The charge air recirculation solenoid is operated by a power feed from the EJB (Engine Junction Box) and a ground connection with the ECM. When it is de-energized, the charge air recirculation solenoid is closed.

If the charge air recirculation solenoid develops a fault it will default to the closed position. In this position an overspeed of the primary turbocharger will occur. This overspeed is sensed by the MAP (Manifold Absolute Pressure) sensor which detects the increase in pressure. The ECM registers the signals from the MAP sensor and operates the turbochargers in mono-turbo mode with restricted engine torque and DTC (Diagnostic Trouble Code)'s recorded.

The charge air shut-off valve is a flap valve operated by a vacuum actuator. The ECM operates the charge air solenoid to apply and release the vacuum in the actuator, which opens the valve when a vacuum is present. When the shut-off valve is open charge air from the secondary turbocharger flows through the valve to the charge air coolers in common with the air flow from the primary turbocharger.

VACUUM CONTROL SOLENOIDS (WHERE FITTED)

| ITEM | DESCRIPTION |

|---|---|

| 1 | Vacuum reservoir |

| 2 | Vacuum connection to turbine intake shut-off valve (secondary turbocharger) |

| 3 | Turbine intake shut-off valve solenoid |

| 4 | Charge air shut-off valve solenoid |

| 5 | Pipe from left air cleaner |

| 6 | Pipe to cooling bypass solenoid of Exhaust Gas Recirculation (EGR) system |

| 7 | Pipe to vacuum actuator of charge air shut-off valve |

| 8 | Non return valve |

| 9 | Pipe from vacuum pump |

The turbine intake shut-off valve and charge air shut-off valve solenoids are installed on a bracket attached to the front of the Bank 2 cylinder head. The ECM operates the solenoids to apply and release the vacuum in the vacuum actuators of the turbine intake shut-off valve (located on the secondary turbocharger) and the charge air shut-off valve.

The vacuum for the actuators is produced by the vacuum pump on the rear of the Bank 1 cylinder head. For additional information, refer to:Engine (303-01A Engine - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation).

The solenoids are normally-closed valves installed in the vacuum line between the vacuum reservoir and their related vacuum actuator. Each solenoid is also connected to a line from the left air cleaner, which allows air into the vacuum lines to the actuators when the solenoids are de-energized.

PRINCIPLES OF VARIABLE VANE OPERATION

The turbine wheel of each turbocharger uses the engine exhaust gases to drive the compressor wheel. The compressor wheel draws in clean air, which is supplied to the engine cylinders in a compressed form.

The primary, VGT turbocharger allows the optimum inlet geometry (inlet area and flow angle) to be used over a wide range of engine operating conditions. This allows a rapid speed of response and higher charge air pressures at low engine speeds. The variable vane angle determines both the inlet area as well as the flow angle, as controlled by the ECM via the VGT actuator. The variable vanes allow efficient use of the exhaust gas energy which in turn improves turbocharger and engine efficiency.

A = LOW ENGINE SPEED; B = INTERMEDIATE ENGINE SPEED; C = MAXIMUM ENGINE SPEED.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Engine Control Module (ECM) |

| 2 | Variable Geometry Turbine (VGT) vane actuator |

| 3 | Turbine housing |

| 4 | Variable vanes |

| 5 | Compressor wheel |

Low Engine Speed. At low engine speeds the volume of exhaust gas is low so the vanes are moved towards the closed position to reduce the turbine inlet area. This reduction causes an increase in the gas velocity into the turbine wheel thereby increasing wheel speed and charge air pressure.

Intermediate Engine Speed. As the engine speed increases and the volume of exhaust gas increases the vanes are moved towards the open position to increase the turbine inlet area and maintain the gas velocity.

Maximum Engine Speed. At maximum engine speed the vanes are almost fully open maintaining the gas velocity into the turbine wheel.

When the vehicle is driven at high altitudes the ambient pressure reduces causing the compressor wheel to rotate faster to achieve the same charge air pressure. To prevent the turbine wheel from over-speeding under these conditions, the ECM protects the turbocharger by opening the vanes further to reduce the turbine wheel speed. This is known as the altitude margin of the turbocharger, which occurs at altitudes above 2000 meters. Below 2000 meters altitude compensation is not necessary. The ECM uses an internal barometric pressure sensor to monitor altitude.

The maximum position of the turbocharger vanes (fully open) is also an emergency default position in the event of an electrical fault. This lowers the chance of engine damage due to excessive charge air pressure.

DUAL MODE BOOSTING (WHERE FITTED)

Ensure both ends of the pipe are securely connected to the secondary turbo and the air intake system to prevent damage to the turbo components.

The dual mode boosting system comprises two turbochargers and software within the ECM. The two turbochargers can operate in two modes; mono turbocharger operation or bi-turbocharger operation.

MONO TURBOCHARGER OPERATION

A = DIRTY AIR; B = CLEAN AIR; C = CHARGE AIR; D = EXHAUST GASES.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Engine |

| 2 | Exhaust system left intake pipe |

| 3 | Primary turbocharger |

| 4 | Left intake grills |

| 5 | Left air cleaner |

| 6 | Left charge air cooler |

| 7 | Charge air shut-off valve |

| 8 | Charge air recirculation solenoid |

| 9 | Right charge air cooler |

| 10 | Right air cleaner |

| 11 | Right intake grills |

| 12 | Electric throttle |

| 13 | Secondary turbocharger |

| 14 | Exhaust system right intake pipe |

| 15 | Turbine shut-off valve |

Fresh air is drawn through the left air cleaner and the MAF (Mass Air Flow) sensor to the primary turbocharger compressor. The compressed air then passes through the charge air coolers and electric throttle to the intake manifolds.

The turbine shut-off valve on the secondary turbocharger is closed and therefore exhaust gases are unable to operate the secondary turbocharger turbine. In this condition all charge air pressure is produced by the primary turbocharger using the exhaust gases from all six cylinders.

If the engine idles for more than 3 minutes, the secondary turbocharger is actuated to keep the turbocharger shaft rotating, to prevent oil from leaking into the turbine housing. This is achieved by periodically opening the turbine intake shut-off valve to operate the turbocharger.

BI-TURBOCHARGER SWITCHING

A = DIRTY AIR; B = CLEAN AIR; C = CHARGE AIR; D = EXHAUST GASES.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Engine |

| 2 | Exhaust system left intake pipe |

| 3 | Primary turbocharger |

| 4 | Left intake grills |

| 5 | Left air cleaner |

| 6 | Left charge air cooler |

| 7 | Charge air shut-off valve |

| 8 | Charge air recirculation solenoid |

| 9 | Right charge air cooler |

| 10 | Right air cleaner |

| 11 | Right intake grills |

| 12 | Electric throttle |

| 13 | Secondary turbocharger |

| 14 | Exhaust system right intake pipe |

| 15 | Turbine shut-off valve |

When the engine operating parameters approach the limits (approximately 2800 RPM under load) of the primary turbocharger, the ECM begins the switch to parallel bi-turbocharger operation. The secondary turbocharger is brought into operation by the opening of the turbine shut-off valve which allows exhaust gases to flow through the turbine. Fresh air is then drawn through the right air cleaner and the MAFT (Mass Air Flow and Temperature) sensor to the secondary turbocharger compressor.

Initially, the secondary turbocharger does not produce a charge air pressure to equal that of the primary turbocharger. Therefore, the charge air from the secondary turbocharger is fed via the recirculation solenoid into the clean air duct of the primary turbocharger.

BI-TURBOCHARGER OPERATION

A = DIRTY AIR; B = CLEAN AIR; C = CHARGE AIR; D = EXHAUST GASES.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Engine |

| 2 | Exhaust system left intake pipe |

| 3 | Primary turbocharger |

| 4 | Left intake grills |

| 5 | Left air cleaner |

| 6 | Left charge air cooler |

| 7 | Charge air shut-off valve |

| 8 | Charge air recirculation solenoid |

| 9 | Right charge air cooler |

| 10 | Right air cleaner |

| 11 | Right intake grills |

| 12 | Electric throttle |

| 13 | Secondary turbocharger |

| 14 | Exhaust system right intake pipe |

| 15 | Turbine shut-off valve |

As the secondary turbocharger charge air pressure increases, the recirculation solenoid is closed and the charge air shut-off valve opened. This increases the charge air pressure from the secondary turbocharger and combines it with the charge air from the primary turbocharger.

The ECM maintains the turbochargers in bi-turbocharger mode until it determines that the engine operating parameters no longer require it. The ECM then switches the turbochargers back to mono turbocharger operation.

SHUT-OFF VALVE CONTROL

Turbine intake shut-off valve: If vacuum is released from the turbine intake shut-off valve it will default to the closed position. The turbine intake shut-off valve position sensor will inform the ECM, which will initiate mono-turbo mode, restrict engine performance and record a DTC.

Charge air shut-off valve: If vacuum is released from the charge air shut-off valve it will default to the closed position. In the default position, the ECM initiates mono-turbo operation and restricts engine torque. A DTC will also be recorded in the ECM.

CONTROL DIAGRAM - SHEET 1 OF 2 - VEHICLES WITH SINGLE TURBOCHARGER

A = Hardwired.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Battery |

| 2 | Battery Junction Box 2 (BJB2) |

| 3 | Battery Junction Box (BJB) |

| 4 | Engine Junction Box (EJB) |

| 5 | Engine Control Module (ECM) |

| 6 | Variable Geometry Turbine (VGT) vane actuator |

| 7 | Charge air temperature sensor |

| 8 | Charge air pressure sensor |

CONTROL DIAGRAM - SHEET 2 OF 2 - TWIN TURBOCHARGER VARIANT VEHICLES

| ITEM | DESCRIPTION |

|---|---|

| 1 | Battery |

| 2 | Battery Junction Box 2 (BJB2) |

| 3 | Battery Junction Box (BJB) |

| 4 | Engine Junction Box (EJB) |

| 5 | Engine Control Module (ECM) |

| 6 | Variable Geometry Turbine (VGT) vane actuator |

| 7 | Charge air temperature sensor |

| 8 | Charge air pressure sensor |

| 9 | Turbine intake shut-off valve position sensor |

| 10 | Turbine intake shut-off valve solenoid |

| 11 | Charge air solenoid |

| 12 | Charge air recirculation solenoid |

FUEL CHARGING AND CONTROLS - TURBOCHARGER - TDV6 3.0L DIESEL

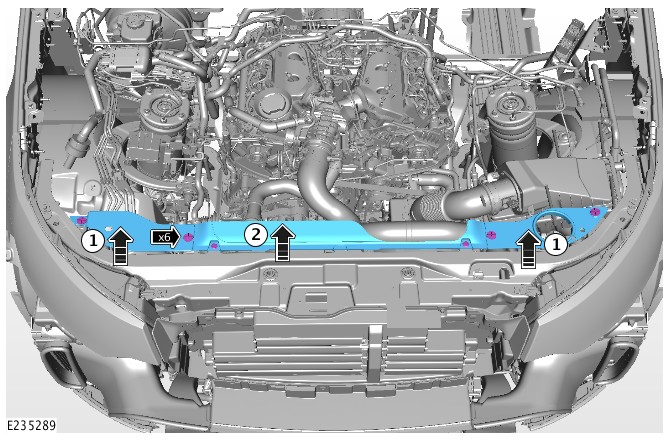

GEN 2 SINGLE TURBOCHARGER (G2055158)

TDV6 3.0L DIESEL - GEN 2 SINGLE TURBOCHARGER

| ITEM | DESCRIPTION |

|---|---|

| 1 | Vacuum reservoir |

| 2 | Variable Geometry Turbine (VGT)- Turbocharger |

| 3 | Vacuum pump (Brake servo assist and turbocharger oil supply pump) |

| 4 | Electronic Vacuum Regulating Valve (EVRV) - EGR control |

This variation of the TDV6 engine has a single Variable Geometry Turbine (VGT) turbocharger mounted on the left side of the engine. This turbocharger is slightly larger in size compared to the primary turbocharger fitted to the twin turbocharger variants of the TDV6 engine. The VGT makes it possible to vary the exhaust gas flow of the turbine, dependent on engine operation. This improves the power transfer to the turbine and compressor wheels, particularly at low engine speeds, thus increasing the boost pressure.

The VGT is connected by the charge air ducts of the intake air distribution and filtering system. For additional information, refer to:Intake Air Distribution and Filtering (303-12A Intake Air Distribution and Filtering - TDV6 3.0L Diesel /TDV6 3.0L Diesel - Gen 1.5/TDV6 3.0L Diesel - Gen 2, Description and Operation). The operation of the system is controlled by the Powertrain Control Module (PCM).

The turbocharger is also cooled with a feed from the main engine cooling system.

VARIABLE GEOMETRY TURBINE (VGT) - TURBOCHARGER

| ITEM | DESCRIPTION |

|---|---|

| 1 | Exhaust gas outlet to exhaust system |

| 2 | Exhaust gas inlet from exhaust manifold |

| 3 | Coolant outlet |

| 4 | Oil pressure supply from cylinder block |

| 5 | Vane actuator |

| 6 | Clean air inlet |

| 7 | Charge air outlet |

| 8 | Coolant feed from cylinder block |

| 9 | Oil feed connection |

| 10 | Oil return connection |

| 11 | Coolant connections |

| 12 | Vane actuator rod |

The Variable Geometry Turbine (VGT) - turbocharger is mounted to the left (bank 2) exhaust manifold.

On production vehicles, no gasket is used to seal the joint surface between the turbocharger and the exhaust manifold. In-service vehicles require a service gasket to be fitted if the joint is disturbed.

The turbocharger consists of two main elements, a turbine wheel and compressor wheel, enclosed separately in cast housings and mounted on a common shaft rotating on two ball bearing races. The ball bearings receive an engine oil feed for lubrication from an outlet at the rear of the engine block, oil then returns to the engine oil pan via an oil drain pipe. Gen 2 engines also have a coolant feed to the primary turbocharger housing from the engine cooling system.

An integral bracket on the compressor side of the turbocharger locates the VGT vane actuator. The VGT vane actuator is connected to an actuator rod which moves the turbine housing to adjust the position of the vanes. When the VGT vane actuator operates, a lever is rotated by a lever arm, which in turn moves the actuator rod and changes rotary motion into linear motion. The actuator rod is connected to a second lever arm attached to the outside of the turbine housing. The linear motion is converted back to rotary motion of the housing and adjusts the variable vanes within the VGT.

The VGT has a connection for the engine cooling circuit to provide the appropriate cooling efficiency of the ball bearing races.

The Powertrain Control Module (PCM) controls the output to the vane actuator motor using a Pulse Width Modulation (PWM) signal. The VGT vane actuator also provides the PCM with a positional feedback signal to determine the pitch angle of the vanes. An angular position sensor in the motor is provided with a 5V reference voltage from the PCM. The position sensor returns a ground and a signal voltage proportional to the actuator position.

The variable vanes in the turbocharger improve the exhaust gas power transfer to the turbine wheel which in turn drives the compressor wheel. This greatly assists the increase in charge air pressure at low engine speeds.

TURBOCHARGER OIL LUBRICATION SYSTEM

| ITEM | DESCRIPTION |

|---|---|

| 1 | Oil feed to turbocharger |

| 2 | Oil feed from cylinder block (T piece) |

| 3 | Vacuum pump (Brake servo assist and turbocharger oil supply pump) |

| 4 | Oil feed from turbocharger oil reservoir |

| 5 | Turbocharger oil reservoir oil filter |

| 6 | Vent pipe |

| 7 | Connection to oil pan oil return pipe |

| 8 | Turbocharger oil return pipe |

| 9 | Variable Geometry Turbine (VGT)- turbocharger |

| 10 | Turbocharger oil reservoir |

| 11 | Oil pan |

| 12 | Vent pipe |

The TDV6 turbocharger system has an oil circuit which is primarily supplied by the engine oil pump and fed to the housing of the turbocharger via an outlet at the back of the cylinder block. Land Rover variants of the TDV6 engine have a vacuum pump driven off the the exhaust camshaft on bank 1, this provides brake booster vacuum and also turbocharger oil supply in certain conditions. The vacuum pump draws oil from a dedicated reservoir within the oil pan via a filter, this oil is then fed to the turbocharger via a port in the cylinder head. The secondary oil feed supplied by the vacuum pump is to make sure that there is adequate lubrication of the bearing races and housing when the vehicle is manoeuvring at extreme angles. The reservoir is replenished with oil from the drain tube below the turbocharger, it also has a breather tube into the cylinder block.

See oil flow diagram at the end of this document.

PRINCIPLES OF VARIABLE VANE OPERATION

Exhaust gases are used to drive the compressor wheel. The compressor wheel draws in clean air, which is supplied to the charge air coolers in a compressed form.

The VGT turbocharger allows the optimum inlet geometry (inlet area and flow angle) to be used over a wide range of engine operating conditions. This allows a rapid response speed and higher charge air pressures at low engine speeds. The variable vane angle determines both the inlet area as well as the flow angle, as controlled by the Powertrain Control Module (PCM) via the VGT vane actuator. The variable vanes allow efficient use of the exhaust gas energy which improves turbocharger and engine efficiency.

A = LOW ENGINE SPEED; B = INTERMEDIATE ENGINE SPEED; C = MAXIMUM ENGINE SPEED.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Powertrain Control Module (PCM) |

| 2 | Primary vane actuator |

| 3 | Turbine housing |

| 4 | Variable vanes |

| 5 | Compressor wheel |

Low Engine Speed: At low engine speeds the volume of exhaust gas is low, so the vanes are moved towards the closed position to reduce the turbine inlet area. This reduction causes an increase in the gas velocity into the turbine wheel, thereby increasing turbine speed and charge air pressure.

Intermediate Engine Speed: As the engine speed increases and the volume of exhaust gas increases the vanes are moved towards the open position to increase the turbine inlet area and maintain the gas velocity.

Maximum Engine Speed: At maximum engine speed the vanes are almost fully open maintaining the gas velocity into the turbine wheel.

When the vehicle is driven at high altitudes the ambient pressure reduces, causing the compressor wheel to rotate faster to achieve the same charge air pressure. To prevent the turbine wheel from over-speeding under these conditions, the Powertrain Control Module (PCM) protects the turbocharger by opening the vanes further to reduce the turbine wheel speed. This is known as the altitude margin of the turbocharger, which occurs at altitudes above 2000 meters. Below 2000 meters altitude compensation is not necessary. The PCM uses an internal barometric pressure sensor to monitor altitude.

The maximum position of the turbocharger vanes (fully open) is also an emergency default position in the event of an electrical fault. This lowers the chance of engine damage due to excessive charge air pressure.

TDV6 3.0L DIESEL - GEN 2 SINGLE TURBOCHARGER OPERATION

A = DIRTY AIR: B = CLEAN AIR: C = COMPRESSED AIR: D = EXHAUST GAS.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Engine |

| 2 | Variable Geometry Turbine (VGT)- Turbocharger |

| 3 | Intake air filter |

| 4 | Charge air cooler |

| 5 | Electric throttle |

Fresh air is drawn through the left intake air filter to the turbocharger compressor. The compressed air then passes through the charge air cooler and electric throttle to the intake manifolds.

A = COOL OIL: B = HOT OIL.

| ITEM | DESCRIPTION |

|---|---|

| 1 | Cylinder head |

| 2 | Cylinder block |

| 3 | Vacuum pump (Vacuum and turbocharger scavenge oil pump) |

| 4 | Turbocharger Oil Supply Filter |

| 5 | Turbocharger Oil Reservoir |

| 6 | Oil Pan |

| 7 | Turbocharger |

TDV6 3.0L DIESEL - GEN 2 SINGLE TURBOCHARGER

A = HARDWIRED: AL = PULSE WIDTH MODULATION (PWM).

| ITEM | DESCRIPTION |

|---|---|

| 1 | Powertrain Control Module (PCM) |

| 2 | Vane actuator |

| 3 | Ground |

| 4 | Supply |

| 5 | Charge air pressure sensor |

| 6 | Charge air temperature sensor |

VACUUM SYSTEM

A = VACUUM SUPPLY: B = VACUUM VENT: C = VACUUM SUPPLY AND VENT: D = FLOW

| ITEM | DESCRIPTION |

|---|---|

| 1 | Exhaust Gas Recirculation (EGR) valves |

| 2 | Electronic Vacuum Regulating Valve (EVRV) - (EGR) valve bypass valve |

| 3 | Active engine mounts |

| 4 | Clean air filter housing |

| 5 | Electronic Vacuum Regulating Valve (EVRV) - Active engine mount solenoid |

| 6 | Brake vacuum reservoir |

| 7 | Brake vacuum non return valve |